A Balanced Solution

Amid surging fuel costs and rising tire prices along with inventory shortages nationwide, it is more important than ever to look at everything a fleet can do to improve tire life and increase fuel efficiency. The answer might be as simple as adding a balancing practice to your fleet’s tire program. Inadequate tire and wheel balance can result in uneven tire wear that prematurely consigns thousands of tires to the scrap pile. Improperly balanced tires and wheels also have a negative effect on fuel economy. Additionally, imbalanced tires and wheels are also responsible for increased wear and tear on other vehicle components and ride complaints from drivers.

Longer lasting tires result in significant savings

Irregular wear can end a tire’s life prematurely. While there are many causes of irregular tire wear, from non-concentric mounting to poor vehicle alignment resulting in cupping/scalloping/wavy wear, spot wear, and flat-spotting, the result is the same: quantities of rubber are scrubbed off the tire over time. A typical deep-tread tire will lose about 30 pounds of tread rubber from the time it’s new until it’s removed at 4/32 of an inch of tread depth. Irregular wear changes the shape of the tire and by extension, the balance of the entire wheel-end assembly. This is where internal wheel balancing products such as Counteract Balancing Beads can really help. Studies have proven, that a balanced tire will wear more evenly and result in tire life increases of up to 50%.

Rolling Resistance and Fuel Efficiency.

Rolling resistance is a measurement of the energy it takes to roll a tire on a surface. For truck tires, rolling resistance has a direct and significant correlation to the fuel economy of the vehicle.

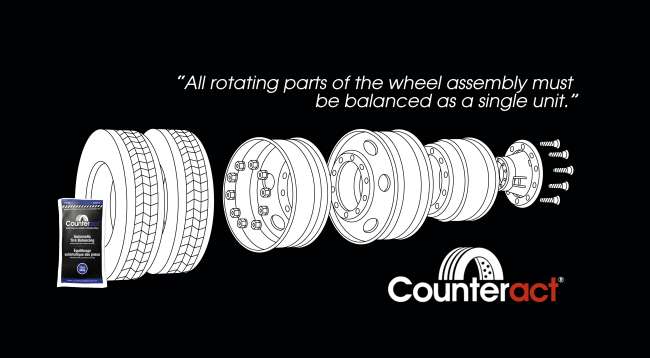

Several factors can influence rolling resistance: including the tread, casing, pressure, and load. Testing has also shown that balancing not just the rim and wheel, but the complete wheel assembly can decrease rolling resistance. Traditional spin balancing of a tire and rim addresses the condition of the assembly only at that moment in time. It does nothing to address the changing condition of the tire as it wears, nor does it address the condition of the wheel hub or brake drum. Those are all parts of the rotating assembly at the end of the axle and need to be balanced as a single unit. Consequently, the time, money, and effort that goes into spin balancing have very little impact on the balance of the wheel over time. An internal balancing agent works to balance the whole wheel assembly and therefore will provide a much greater return on investment.

It has now been proven in two separate SAE J1321 fuel-economy tests, one conducted by Auburn University the other by the PIT Group (The results of both tests showed the use of Counteract Balancing Beads in all wheel positions increased fuel efficiency by 2.2%.

As fleets navigate a future with rising fuel and tire costs, it’s more important than ever to look to solutions that provide a clear and proven return on investment. To learn more about the benefits of balancing the complete wheel assembly visit www.counteractbalancing.com or reach out to one of our trained fleet specialists to learn what Counteract Balancing Beads can do for your bottom line.

Counteract Balancing Beads are the industries leading internal tire balancing product, with over 25 years of experience and millions of applications worldwide. Counteract is the only internal tire balancing product to prove fuel economy improvements in two separate SAE J1321 fuel-economy tests, one conducted by Auburn University the other by the PIT Group.

The above article is sponsor-generated content. To learn more about sponsor-generated content, click here.