Taking a Look Under the Hood of Electric Trucks

[Stay on top of transportation news: Get TTNews in your inbox.]

The introduction of electric-powered trucks represents a new frontier for the transportation industry, but this new breed of commercial vehicle will not be completely unfamiliar to fleets and maintenance shops.

While electric trucks incorporate systems and technologies that will be new to trucking operations, they also feature many of the well-known components present in diesel trucks.

And much like modern diesel powertrains, electric propulsion systems will monitor their components’ operation and generate diagnostic codes when there is trouble.

The precise and efficient control of electric motors will be a brave new world of advanced electronics, but the self-diagnosing capabilities of electric trucks should help mitigate concerns about the learning curve associated with maintaining and repairing these vehicles.

Electric motors have torque characteristics somewhat similar to those of diesels, but provide a good deal more of that torque at low rpm and do it right down to zero rpm, industry experts explained. This means that electric drivetrains frequently will resemble what maintenance managers and technicians are used to, often to the point of including familiar multispeed transmissions to optimize performance and minimize motor weight. One key difference will be fewer gears, depending on application.

Some trucking industry suppliers prefer to utilize the inherently high motor torque without adding changeable ratios. Several suppliers, though, will use familiar drivetrain layouts including a transmission, driveshaft and rear axle or axles, all including gear reduction.

Much like diesel engines, electric motors and especially batteries have favored operating temperature ranges. Industry experts said batteries charge best when warm, so when equipped with cooling systems, those systems usually include a heating function. Electric motors also operate best when held to the proper operating temperature, and lose efficiency and reliability when running hot. Thus, technicians will see familiar cooling systems filled with ethylene-glycol antifreeze, with the biggest difference being the provision of electrically driven coolant pumps.

One of the major advantages of electric motor-driven trucks is the ability to provide regenerative braking. Unlike a diesel, an electric motor can recover energy by efficiently sending charging current back into the batteries in a precisely controlled process. This not only reduces operating cost and extends range, it also reduces brake pad and lining wear, experts said.

Dana Direct Drive System by Transport Topics on Scribd

Fleet executives and maintenance staff will need to become acquainted with two areas of radically new technology. One area is the batteries that store energy, and the other is the power controller that converts the direct current produced by the batteries to alternating current for the motors in an appropriate form for the conditions.

“Batteries will come in various chemistries, but lithium-ion-cobalt and ion phosphate will be the major types,” said Vinoo Thomas, general manager of Cummins’ electrical powertrain business. “They will come in multiple formats. Design considerations include, of course, cost, but also efficiency, packaging and, above all, life.”

He believes they will need to last 10 to 15 years to satisfy the market.

Their voltage output will have to be considerably higher than what is used in present truck electrical systems, Thomas said.

“You need to control the amps,” he said. “Unless you provide enough voltage, there are penalties in efficiency, and you have to maintain the wire size at a manageable level.”

He said Classes 3-4 trucks are likely to run at 300-400 volts, while Class 8 tractors will use 650 volts.

John Moore, product marketing manager at Volvo Trucks North America, also discussed the composition of electric vehicle batteries.

“Lithium-ion batteries are composed of lithium and graphite with a solid electrolyte, and have a higher energy density that allows continuous power output over a long period of time, compared to lead-acid batteries designed to provide short bursts of high amperage over a short period of time to crank an engine,” Moore said. “These batteries are maintenance-free and require no addition of water but should always be visually checked during a pre-trip inspection.”

Industry suppliers such as Dana are offering a range of electric-truck systems, including batteries.

Cummins technicians look at battery modules. The diesel engine maker is one of several major industry suppliers investing in commercial vehicle electrification. (Cummins)

“Dana supplies both lithium nickel manganese cobalt and lithium ion phosphate-based battery chemistries, depending on the requirements of each application,” said Steve Slesinski, director of global product planning.

These batteries are packaged to sustain vibrations and are thermally managed to offer performance in environments from -22 to 113 degrees Fahrenheit. They can sustain more than 4,000 charge and discharge cycles with less than 20% capacity degradation, he said.

Some of Dana’s batteries won’t need cooling, but they all will have heating available for extreme cold.

Cummins’ Thomas added that the primary maintenance item for the batteries will be the fairly typical ethylene-glycol cooling system most battery packs will require.

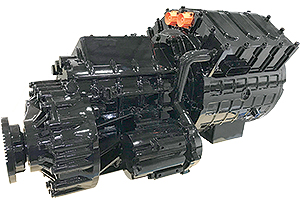

A Cummins integrated electric motor and transmission. (Cummins)

Sources explained that batteries can deliver and be charged only by DC — direct current. But, all the motors in truck drivetrains will be motors that use alternating current, or AC, because that process is more efficient, and AC motors don’t need brushes, they said. The power controller either includes or is paired with an inverter.

“An inverter transforms DC into AC and controls the frequency of power supplied to the motor to control speed of rotation,” Dana’s Slesinski said.

Cummins’ Thomas said electric motors have great torque and respond instantly, “so you can have lurching, which ultimately can mean broken parts.”

Thus, there will be “a significant number of sensors and the control must be very precise,” he said.

T.J. Reed, vice president of global electrification at Meritor, described the function of the powertrain controller as “the link between the vehicle and the motor.”

He said it will “listen to the vehicle, and will then talk to the motor and tell it what to do,” explaining a complex, nuanced process.

Slesinski and Thomas pointed out that the controller also must be able to reverse the process so the motor produces drag rather than forward torque, thus generating a current that will be converted to DC and sent to the batteries or, as Thomas indicated, when the batteries are nearly charged, to be blended with current sent to resistance banks.

All sources said the motors will have maintenance-free, sealed and permanently lubricated bearings.

Different electric truck models will feature significant variations in system architecture.

“We need to figure out the best solutions and be flexible, as we need to integrate our power system across a variety of OEMs, and also adapt to Class 8 vehicles as well as buses,” Cummins’ Thomas said.

“With proper integration, electric drive systems can shine,” he added, “[but} you need to multiply the torque, especially for Class 8 trucks.”

Thus, Cummins will use 2-speed transmissions for lighter trucks, such as Classes 3-4 vehicles, while Classes 7-8 will have a 4-speed conventional truck transmission with pressure lubrication and a cooler.

“You need this to make steep grades like those gaining access to the Gerald Desmond Bridge near the Port of Long Beach,” Thomas said.

Electric trucks feature extensive cooling systems for the batteries, controllers and electric motors. (Mack Trucks)

Cummins’ electric architecture puts the complexity in the front of the vehicle, as company engineers think that putting most components near the rear limits flexibility.

The Cummins system will use a conventional driveshaft and rear axle or axles, though the components are substantially strengthened “because of the need to handle more backward torque, which also means more end-thrust in the drive axle.”

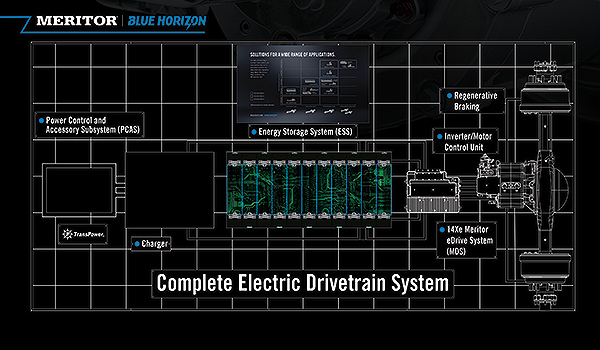

Meritor’s Blue Horizon brand electric drivetrain technology offers a different architecture.

Reed described the company’s approach as an e-axle, consisting of a motor and transmission integrated into the carrier of the drive axle.

“It will all be packaged into a traditional axle housing that fits into today’s suspension architecture,” he said.

Advantages of this arrangement, Reed said, include lower weight and elimination of the need for a longer wheelbase.

“The system will use current bearings and wheel-end equipment off the shelf,” he said, “keeping costs down and maximizing reliability and durability.”

Meritor’s Blue Horizon electric drive system includes a charger, batteries, eDrive controls and the 14Xe axle. (Meritor Inc.)

The system will have a 2-speed transmission to keep the motor in its “sweet spot” at various vehicle speeds to provide maximum efficiency while a 3-speed is in development, he said.

Classes 5-6 trucks with 4×2 axle configurations will incorporate Meritor 14Xe or 12Xe hardware, with the 12Xe being available for vehicles with 17.5-inch wheel equipment, in which lower ground clearance is required. Class 7 single axle and Class 8 6×4s will use 14Xe hardware.

“Because of the regeneration demand on the gearing of the axle, we changed the materials down to the microstructure in the gears to make them more robust,” Reed said.

Meritor’s batteries will be of the lithium-ion type and include active thermal management. The batteries, supplied by wholly owned subsidiary TransPower, will be nominally rated at 675 volts with an operating range of 550-750 volts, and with an overall capacity of 500 kilowatt hours.

Meritor will provide the powertrain controller and motor inverter with the e-axle, and the OEM will provide the vehicle unit controller.

Much of the trucking industry relies on older onboard technology for critical functions, which can hurt reliability and efficiency. So is it time for fleets and their technology vendors to implement faster replacement cycles for onboard tech? Seth Clevenger talks to Ray Greer of Omnitracs and Deryk Powell of Velociti. Hear a snippet, above, and get the full program by going to RoadSigns.TTNews.com.

Peterbilt Motors Co. is using the TransPower energy storage subsystem and a Meritor Blue Horizon midship motor drive subsystem in its Model 579EV.

Dana’s Slesinski said electric-truck architecture “is configured based on volume, utilization, noise vibration and harshness prevention, and cost.”

He said, in Dana’s view, “The current popular applications for battery-electric vehicles do not require a transmission with shiftable gear capability.”

The company offers multiple electric powertrain configurations.

“Dana’s most popular e-powertrain option is the central drive motor configuration which has the torque and speed range to eliminate the need for additional gears altogether,” Slesinski said. “Dana also offers an e-axle configuration, a single speed-reduction axle for these same applications. This solution, too, has no shift interrupts for smooth, quiet operation through a broad range of speeds and grades.”

The company’s TM4 motors are protected against overheating by limiting the power should the motor reach an upper limit.

Kenworth Truck Co. is collaborating with Dana on electric powertrain development, and showed a Kenworth K270E battery-electric vehicle in January at CES in Las Vegas.

Daimler Trucks North America has introduced battery-electric versions of its heavy-duty Freightliner Cascadia and medium-duty M2 models.

“Both the eCascadia tractor and eM2 will be powered by ‘e-axles’ — a combined motor and transmission assembly, mounted directly to the rear axle,” said Andreas Juretzka, head of e-mobility at DTNA.

Those e-axles will be cooled by a liquid thermal management system, powered by an electric pump, he said.

DTNA has delivered battery-electric versions of its Freightliner Cascadia and M2 models to fleet customers for testing. (Daimler Trucks North America)

“With an ‘e-axle’ motor assembly, the motor and transmission share a common housing with the rear axle — eliminating the need for a driveshaft,” Juretzka said. “With electric motors, the need for multiple gears to optimize RPM is not necessary, as they can operate over a wide range of RPMs while providing sufficient torque. Nevertheless there is a sweet spot area in the efficiency mapping. The gear set for these vehicles is sufficient to optimize both gradeability and energy efficiency at cruising speed.”

The eCascadia and eM2 will utilize high-voltage, lithium-ion batteries mounted under the frame rails.

These electric vehicles also will have diagnostics capabilities similar to what fleets have come to expect from diesel-powered trucks.

“The electric powertrain in the eCascadia and eM2 will be equipped with sensors to produce fault codes similar to Daimler’s traditional powertrains, enabling many of the same telematics and diagnostics features that Freightliner customers already utilize via Detroit Connect, DiagnosticLink and Detroit Virtual Technician,” Juretzka said.

Volvo’s Moore said the company’s electric-truck driveline consists of dual electric motors coupled to a 2-speed transmission located between the frame rails behind the cab. The transmission has a lower speed to provide necessary starting tractive efforts. The electric driveline assembly is connected to the rear differential via a prop shaft.

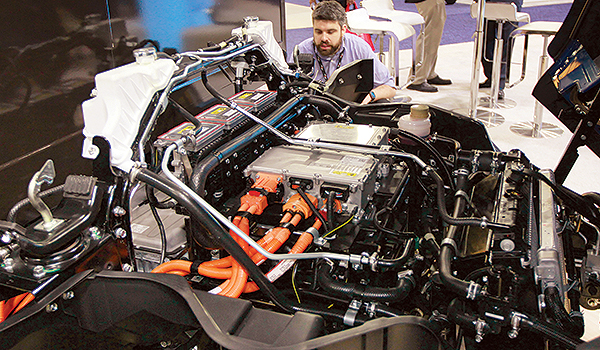

A trade show attendee looks inside the electric Fuso eCanter medium-duty truck. (John Sommers II for Transport Topics)

“The electric driveline provides the amount of power and torque necessary to achieve the desired amount of vehicle speed the driver is requesting for the given terrain at a given gross vehicle or combination weight,” Moore said. “The software is designed to provide an efficiency-performance blend that optimizes the driving experience.”

Volvo also gives drivers the ability to control the level of regenerative braking.

“The Volvo VNR Electric has a multiposition stalk allowing the drive to choose how much regenerative braking is necessary, manually based on preference, or through auto mode, where the system decides based on vehicle speed, load and grade how to maximize the energy returned to the batteries,” Moore said.

Roy Horton, director of product strategy at Mack Trucks, said that the Mack LR Electric refuse truck utilizes four lithium-manganese cobalt-oxide batteries operating at 600 volts.

“This vehicle is equipped with an electric drivetrain mounted in a proven configuration. Both the two AC motors and the Mack Powershift 2-speed transmission are mounted between the frame rails, driving standard Mack tandem rear axles,” Horton said. “The transmission is also cooled by the truck’s thermal management system.”

It’s clear these new electric trucks will require much of the same hardware maintenance that fleets already are familiar with, along with some fresh challenges — challenges the component providers hope to minimize with the right onboard diagnostics and in-shop tools.

Want more news? Listen to today's daily briefing: